Mercedes and Siemens Develop Digital Energy Twin

The aim is to improve the interplay between energy efficiency and sustainability in factory planning.

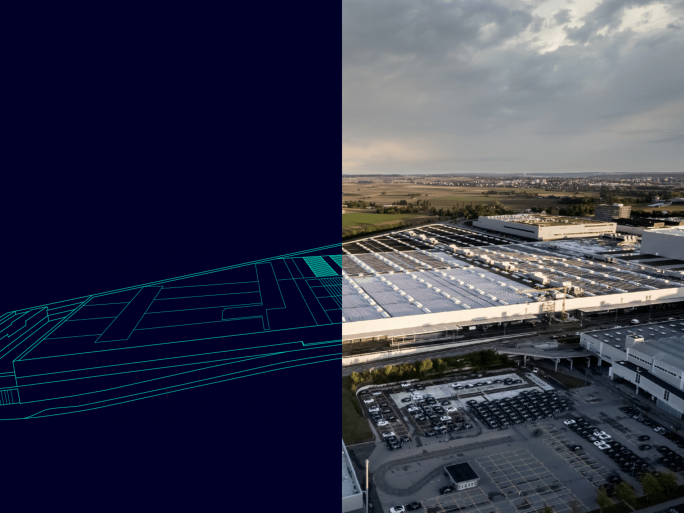

The “Digital Energy Twin” is intended to significantly shorten the early planning phase. The solution should help the Sindelfingen-based company to operate all of its own production sites worldwide with 100 percent renewable energy by 2039. The twin is intended to simplify and accelerate energy planning in the early phase. This should noticeably shorten the planning time. The tool was developed and tested at the Mercedes-Benz plant in Sindelfingen.

Based on so-called behavioral models of buildings, technical systems and energy generation facilities, the twin links a wide range of information, such as weather data, load profile simulations, information on system selection and dimensioning. By simulating a physical energy system, proposed planning scenarios for energy consumption are verified and recommendations are made for optimizing the desired results, including energy efficiency and the associated cost savings and emission reductions.

Recommendation engine

The collaboration combines Siemens’ expertise in the areas of decarbonization and digital energy twins with Mercedes-Benz’ automotive know-how. Siemens provides training and support services for the digital energy twin and is responsible for its maintenance and further development so that it can be used throughout Mercedes-Benz’s global production network.

“Thanks to the accurate modeling of operational and energy usage scenarios, the digital energy twin enables faster and more transparent decision-making in early planning phases,” says Matthias Rebellius, Member of the Managing Board of Siemens AG and CEO of Smart Infrastructure. “This demonstrates how we at Siemens are connecting the real and digital worlds to drive scalable, sustainable progress in the industry. It is an exciting first step towards an integrated process for optimized planning, building operations and production.”